Tool Theory

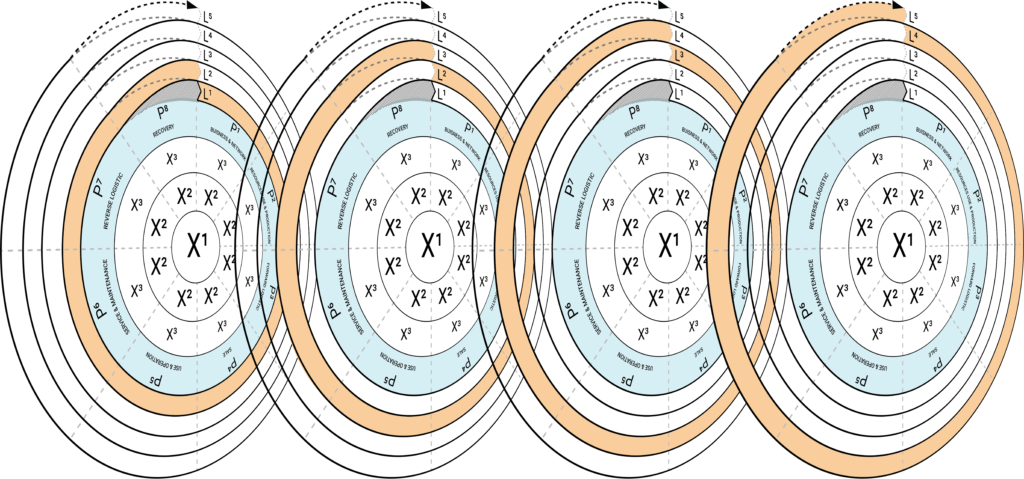

Why this framework? During my research, I came across many intertwined circular design strategies that made challenging for designers to define their own strategies and have a meaningful impact on product circularity. To help all designers in framing a better circular design scheme, I decided to organize circular design strategies in relation to product lifecycle. Based on a scientific method, I designed the framework shown here. This framework can help to creatively generate multiple viable circular business models.

Scroll down

↓

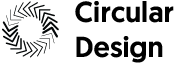

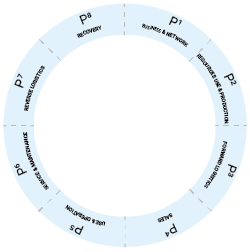

Structure of the framework

Each design strategy is interconnected and may influence other decisions at any level of the design process.

Each design decision should be taken in relation to each phase of the product lifecycle.

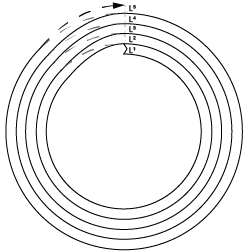

Each lifecycle should be structured and planned considering the overall product lifetime.

What are the main circular objectives? The aim of the circular economy is to design a value that can be recaptured multiple times for multiple monetary flows. For designers, it is crucial to define objectives to develop and structure the desired outcome. In the circular context, the only way a product can generate multiple cash flow for each loop is by using one of the following alternatives:

1. Maintenance;

2. Reuse;

3. Refurbish;

4. Remanufacture;

5. Upcycling;

6. Recycle

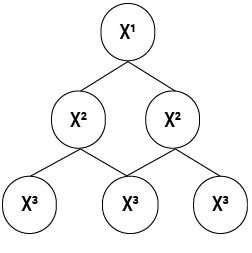

X1 in the Multi-hierarchical DfX framework corresponds to the main circular objective.

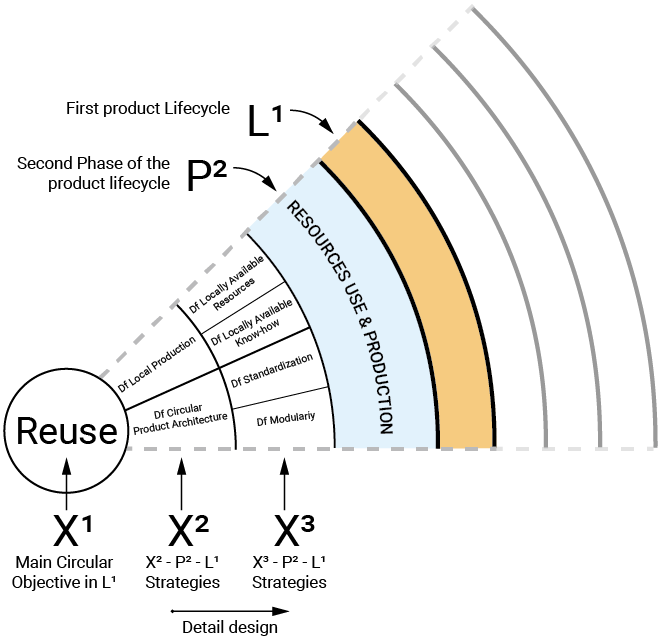

Example of a possible strategic plan (detail of P2)

X1 - Main circular strategy

The X1 strategy represents the only and the first strategy that the company needs to define when designing for the circular economy. It identifies the general circular business approach for each Loop (L). Therefore it will define all the other design strategies (X2 and X3) for each phase of the design process of the same Loop. Designers can substitute X1 with one of the following design strategies:

1. Design for Maintainance;

2. Design for Reuse;

3. Design for Refurbish;

4. Design for Remanufactured;

4. Design for Recycle.

P1 - Business & Network

The P1 represents the Phase (P) in which the business model is determined. In this phase is defined how the company/ies and the stakeholders should create, deliver and capture value in each loop (L).

X2 in P1

The X2 in P1 strategy represents the main strategy or strategies business designers can use in order to make X1 possible.

X3 in P1

The X3 in P1 strategy represents the strategy or strategies business designers can use in order to make X2 possible.

P2 - Resources use & Production

The P2 represents the Phase (P) in which the resources use and production is determined. In this phase is defined how the company/ies and the stakeholders should create, deliver and capture value in each loop (L).

X2 in P2

The X2 in P2 strategy represents the main strategy or strategies industrial engineers can use in order to make X1 possible.

X3 in P2

The X3 in P2 strategy represents the strategy or strategies industrial engineers can use in order to make X2 possible.

P3 - Forward Logistics

The P3 represents the Phase (P) in which the forward logistics is determined (from raw materials to end-user). In this phase is defined how the company/ies or stakeholders organize the infrastructural movement of the value in each loop (L).

X2 in P3

The X2 in P3 strategy represents the main strategy or strategies logistics engineers can use in order to make X1 possible.

X3 in P3

The X3 in P3 strategy represents the strategy or strategies logistics engineers can use in order to make X2 possible.

P4 - Sale

The P4 represents the Phase (P) where it is determined how to sell the value. In this phase is defined how the company/ies or stakeholders sale the value to the final-user for each loop (L).

X2 in P4

The X2 in P4 strategy represents the main strategy or strategies marketing designers can use in order to make X1 possible.

X3 in P4

The X3 in P4 strategy represents the strategy or strategies marketing designers can use in order to make X2 possible.

P5 - Use & Operation

The P5 represents the Phase (P) where it is determined how users will use the value. In this phase is defined how the company/ies or stakeholders design the value for the different final-users for each loop (L).

X2 in P5

The X2 in P5 strategy represents the main strategy or strategies industrial designers can use in order to make X1 possible.

X3 in P5

The X3 in P5 strategy represents the strategy or strategies industrial designers can use in order to make X2 possible.

P6 - Service & Maintainance

The P6 represents the Phase (P) in which the value is maintained through related services. In this phase is defined how the company/ies and the stakeholders should provide the maintenance of the value in each loop (L).

X2 in P6

The X2 in P6 strategy represents the main strategy or strategies service designers can use in order to make X1 possible.

X3 in P6

The X3 in P6 strategy represents the strategy or strategies service designers can use in order to make X2 possible.

P7 - Reverse Logistics

The P7 represents the Phase (P) in which the reverse logistics is determined (from end-user to recovery or to a new user). In this phase is defined how the company/ies or stakeholders coordinate the infrastructural return of the value in each loop (L).

X2 in P7

The X2 in P7 strategy represents the main strategy or strategies reverse logistics engineers can use in order to make X1 possible.

X3 in P7

The X3 in P7 strategy represents the strategy or strategies reverse logistics engineers can use in order to make X2 possible.

P8 - Recovery

The P8 represents the Phase (P) in which the recovery of the value comes about. In this phase is defined how the company/ies or stakeholders coordinate the recovery of each part of the product each loop (L).

X2 in P8

The X2 in P8 strategy represents the main strategy or strategies recovery designers can use in order to make X1 possible.

X3 in P8

The X3 in P8 strategy represents the strategy or strategies recovery designers can use in order to make X2 possible.

L1 - First product lifecycle

In L1 the product is new and usually, this is the most easy design process to design. However, from the good management of this loop depends the succesfully of the next loops (L2, L3, etc).

L2 - Second product lifecycle

In L2 the product is in its second lifecycle. From this loop on out, the product may have been reused, refurbished, remanufactured, or recycled. All the loops after the first are more difficult to manage because the company should take into consideration different factors for each of the different loops, such as recovery, market, target, etc.